MFG Automations Patent Pending Turban Vane Cleaning Process

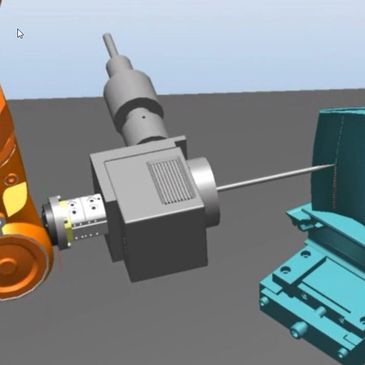

Process Modeling

Precise Positioning

Process Modeling

The process is modeled and validate:

- Part data acquisition and calibration linking each point of the turban vane to its SN

- Laser path profiles for each vane

- Dimond grind finishing path profiles for each vane

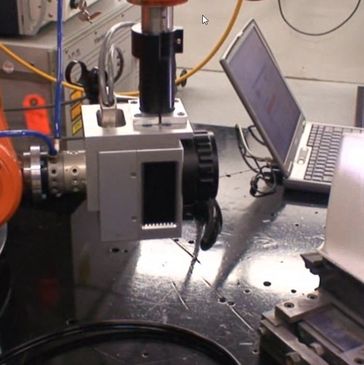

Laser Drilling

Precise Positioning

Process Modeling

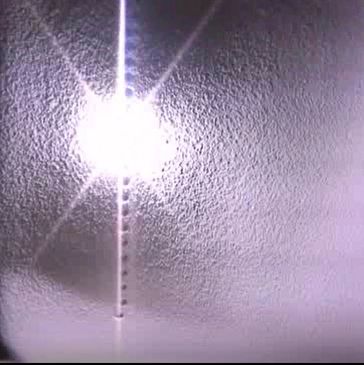

The laser bores the plasma surface without penetrating the metal surface.

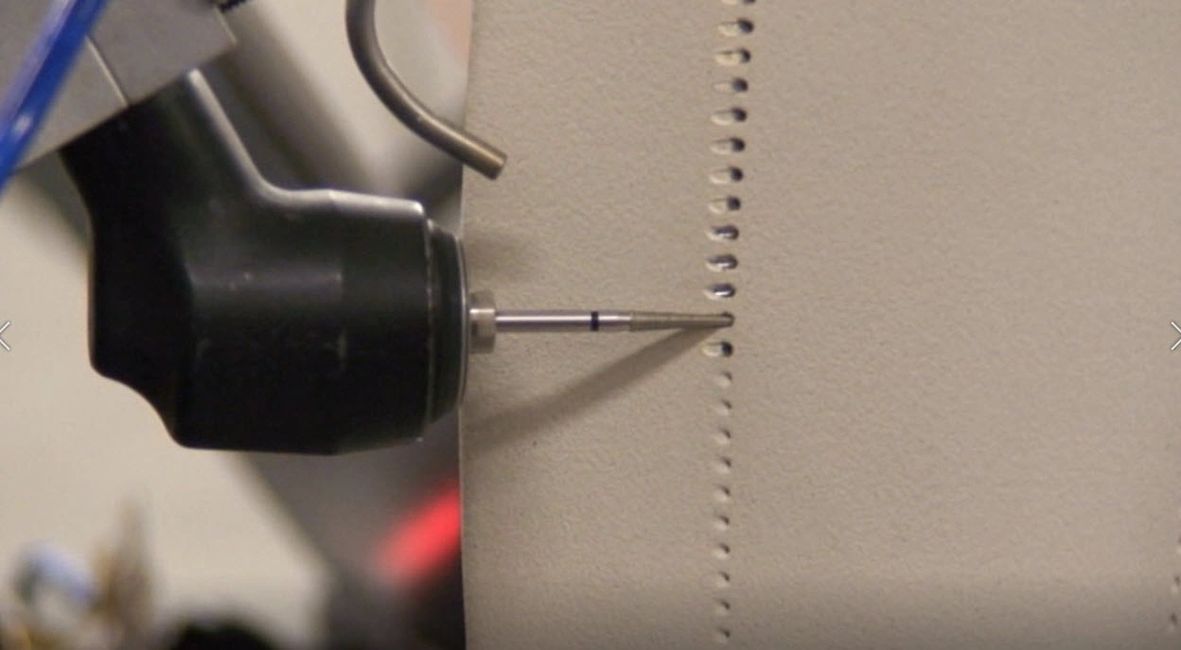

Precise Positioning

Precise Positioning

Precise Positioning

Precise drilling without impacting neighboring vanes. The focal point of the laser is sized for the vane opening concentrating its energy on the plasma spray over it.

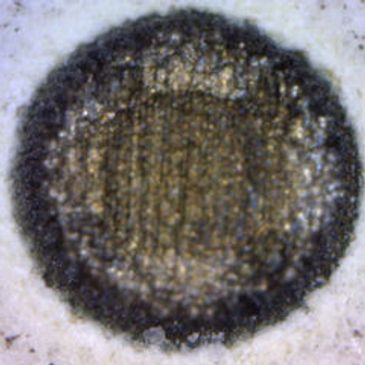

Magnified 250x

Magnified 250x

Magnified 250x

The laser drilling process is so accurate that we can bore only the plasma material without distorting the metal below.

Plasma Spray

Magnified 250x

Magnified 250x

When a turban vane is plasma sprayed some vanes may be completely hidden from view

Magnified 250x

Magnified 250x

Magnified 250x

The laser completely vaporizes the surface of the plasma spray covering the vane and only targets the material on the inner perimeter of the vane. In addition, cut away samples confirm that no foreign material can be found within the vane.

Robotic Diamond Grind

Perfectly Aligned

The final part of the process is the diamond grind. Each hole entry is aligned with the axial axis of the vane. In addition, the finished conic entry of the vane is the same from vane to vane.

Higher Quality, faster, and lower consumable cost

The total process time per hole is in the order of 10 seconds. Most importantly the life of the diamond bit is extended by 300%. The combination of robot, laser, and grinding significantly reduces process time and consumable cost..

One Year of Testing & Process Vaildation

Phase 1 Design Objectives

- Repeatable

- Accurate

- Fast

- Automatic

- 50% Consumables Reduction

Phase 2 Process Validation

Proof of concept with exceptional results.

Four Second Finishing Cycle

MFG AUTOMATION LLC

32 Nott Highway, Ashford, Connecticut 06278, United States

Copyright © 2020 MFG AUTOMATION LLC - All Rights Reserved.

Powered by GoDaddy Website Builder