Engineering

Evaluations

Evaluations

Evaluations

Feasibility surveys are conducted on all opportunities we consider

Training

Evaluations

Evaluations

MFG conducts both project training as well as innovation seminars

Design

Evaluations

Design

Core project design considerations in every application. If needed designed and built by MFG

- End-of-arm-tools

- Fixtures

- Multi tool configurations

- Part handling equiment

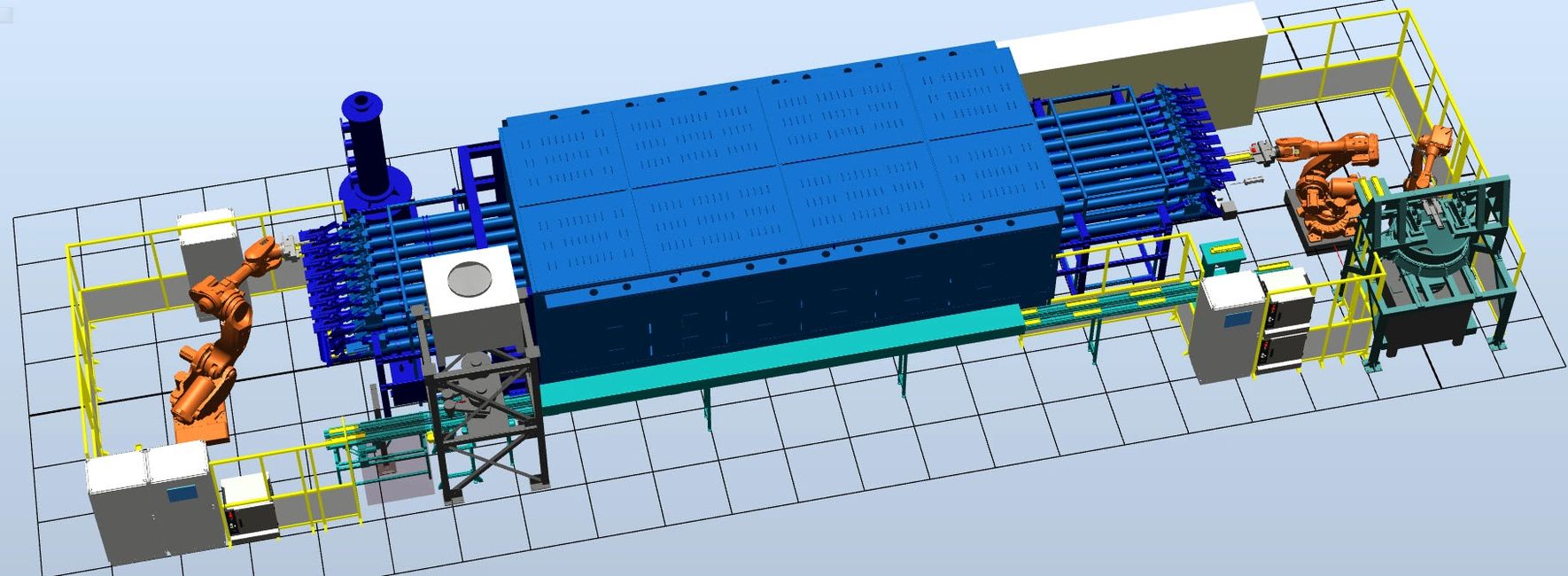

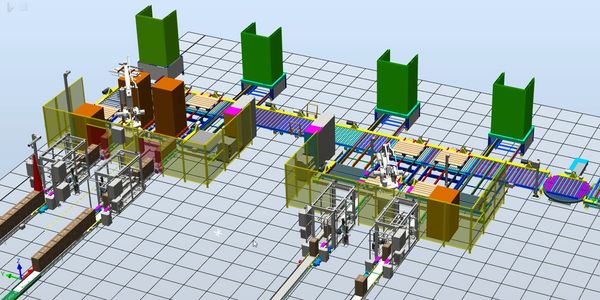

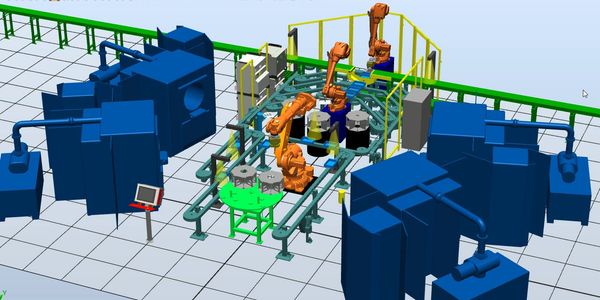

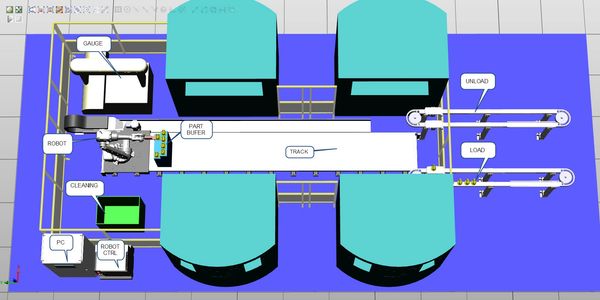

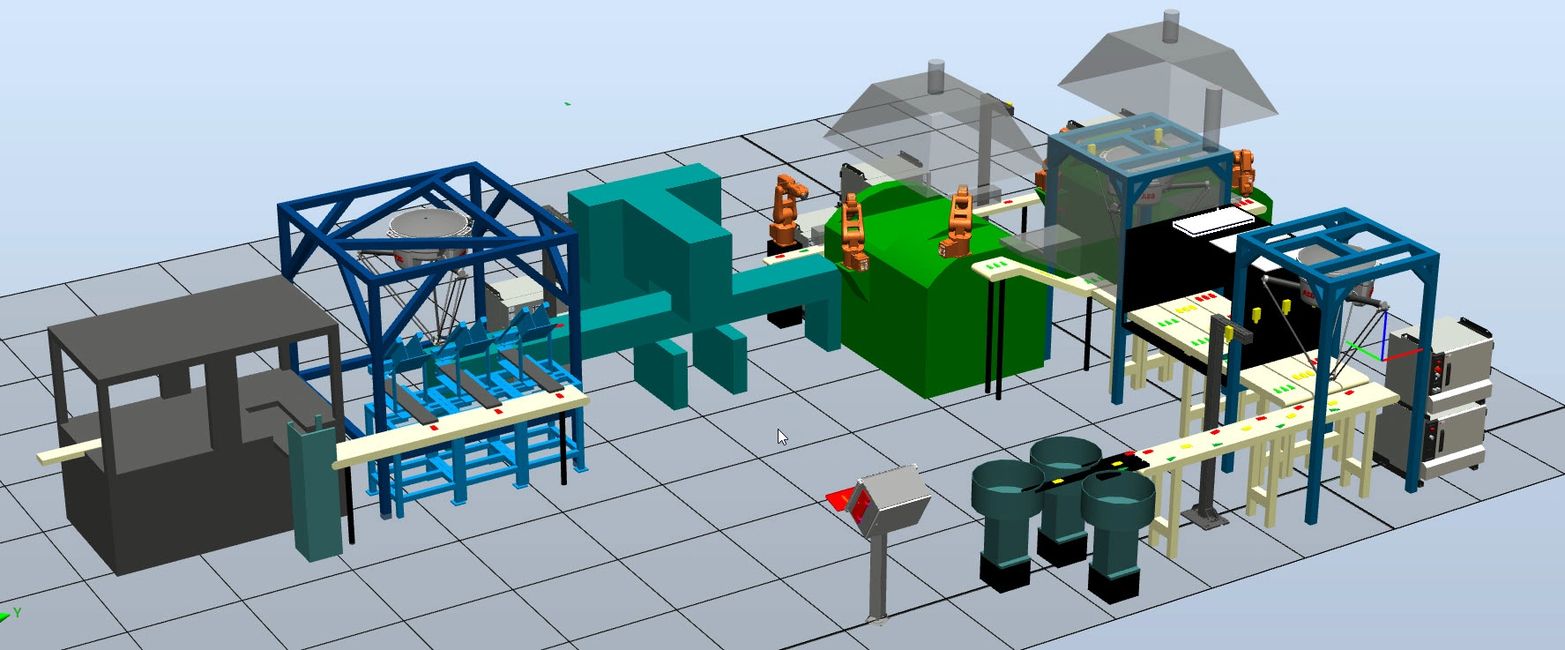

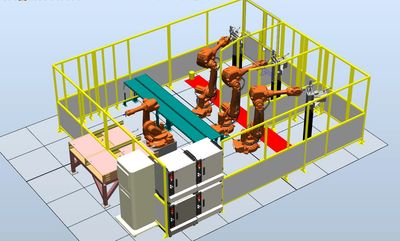

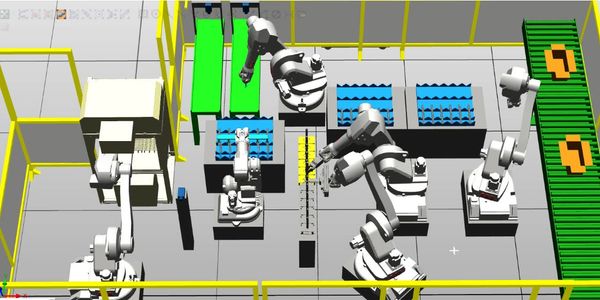

Concept Modeling and 3D Application Testing

Validating the Design

Unfortunately our robotic cells are not off-the shelf products. They are tailored to a customers specific needs. As such, we invest a great deal of effort modeling each cell and validating the concept for key process parameters before every quote;

- Reach

- Payload

- Speed

- Performance

The MFG Difference

Many times product dynamics cannot always be measured or realized in the animated environment. We anticipate implementing field changes as required to ensure system performance.

MFG Cell Designs

< Palletizing

Plastic Injection >

< Pharmacutical

High Speed Packaging & Inspection

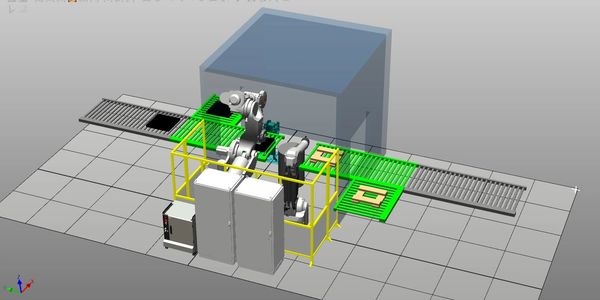

Many applications are smaller in scope.....

Project Size

Not all of our applications are large, many are smaller in scope. Some are single robot applications. Regardless of the jobs size the process is the same, we check, check, check and check before we quote! This provides our clients with a sound understanding of the proposed systems performance and deliverables.

Other MFG Designs

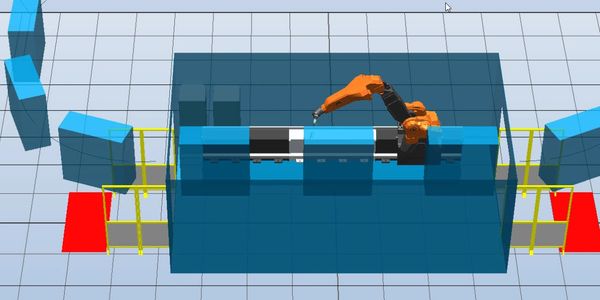

< Large Part Manipulation

- Pick and identify 100 lb. part

- Articulate for paint robot to reach all areas

- Place painted part on shipping pallet.

In Process Painting >

Synchronized painting of moving parts

< Inspect & Pack

- Identify Parts

- QC

- Multiple group pack option

Design & Build

We are not your ordinary Robotic Integrator. When necessary we can custom design and fabricate parts and assemblies. Our objective is to use standard products when available. However, rather than designing around available parts and reducing performance we preferer to maximize performance.

Meeting Spec

Rotary table custom designed and built - 185,000 lb. load capacity with precision positioning. We rarely secure your typical robotic pick & place applications. More often than not we are pushing the technological envelope in one form or another to meet specific customer specifications.

Our systems are fully integrated with the latest user interfaces and networking technologies.

MFG AUTOMATION LLC

32 Nott Highway, Ashford, Connecticut 06278, United States

Copyright © 2020 MFG AUTOMATION LLC - All Rights Reserved.

Powered by GoDaddy Website Builder